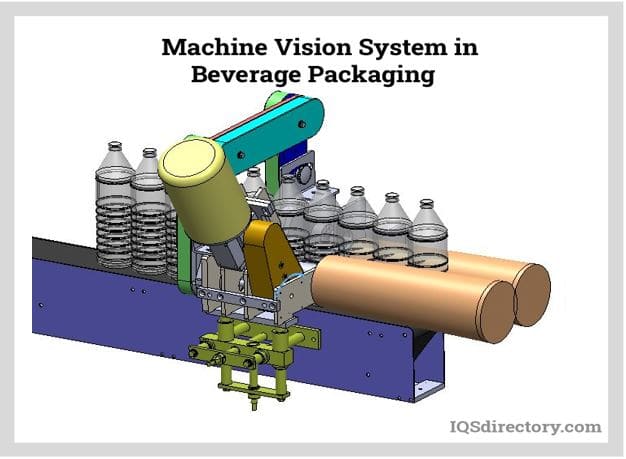

Machine vision systems can be defined as some kind of technology that enables the inspection, evaluation, and identification of still, or moving, images by a computing device. This technology relies on a variety of methods which can be used for different applications ranging from identifying item defects, barcode reading, and product sortation to product checking, end-of-line vehicle inspection, and robotic production. Read More…

When it comes to machine vision systems, we have the tools to get the job done right. We work hard to provide the best solutions and products to meet our customers’ demand. It is our goal to work with you from start to finish on all aspects of design and production. We will do our best to provide the solution to even your most challenging requirements. Find out more by contacting us today!

A family-owned business since 1923, Barr-Thorp Electric Company, now known as Thorp Controls provides electrical control solutions for OEMs, system integrators, and industrial users. From sourcing to engineering to installation and beyond, you can rely on us for efficient, reliable solutions. Our goal is to provide you with the technology you need to be more profitable. Our machine vision...

PrimeTest Automation is a full service systems integration company with a talented in-house engineering team featuring mechanical, electrical, and software engineers. Services include: conveyor systems, machine vision components, robotic systems and rotary index dials. All systems are modeled using the latest 3-D design software, thoroughly reviewed with the customer.

Imperx Inc. is a designer and manufacturer of high performance machine vision products, specifically digital cameras and frame grabbers. Industries served include the aerospace, industrial, commercial, and military industries. Product applications include biometrics, aerial mapping, traffic management, surveillance, homeland security, medical imaging, printing, and more.

More Machine Vision System Manufacturers

Types of Machine Vision Systems

The different types of machine vision systems include:

1D Vision Systems

These systems analyze the digital signal one line at a time rather than looking at a complete picture. These systems work by looking for any variance between the lines that were previously acquired and the lines that are subsequently acquired. 1D machine vision systems have the main function of detecting and classifying defects in materials that are manufactured in a continuous process like plastics, paper, metals, and many non-woven items.

2D Vision Systems

Two Dimensional vision systems provide area scans that work well for discrete parts. They are very compatible with many software packages. They are also the default technology that is used in many machine vision applications. They are found in continually-expanding resolution ranges.

3D Vision Systems

There are many different types of 3D machine vision systems. Stereo systems are used for capturing three dimension information by the use of two cameras that are horizontally displaced from one another. Each camera will provide an object image that is slightly different in projection from the others. The matching of points in one image with the same set of points in the second image is then possible. This task is called the correspondence problem.

Applications of Machine Vision Systems

Below is a list of some possible machine vision system applications:

- Barcode reading

- Defect detection

- Sorting

- Vision-guided robots

- Traceability

- Pattern matching

- Recognition and verification of optical character

- Color verification

- Automated vision testing as well as measurement

- Presence/absence detection

- Part verification

Benefits of Machine Vision Systems

The benefits of machine vision systems include:

Lower Costs

Machine vision systems improve manufacturing speed and reduce the amount of labor needed for operating the equipment. Machine vision systems also reduce scrap rates so there is a reduction of wasted materials.

Elimination of Human Errors

Since the human eye is not infallible, machine vision systems help in ‘qualitative interpretation’ by reducing human subjectivity during production processes. For the inspection of object details that are too small for discernment by the human eye, machine vision systems can be paired with high-resolution cameras. These vision systems can further eliminate operator fatigue as well as variances between different operators.

Machine vision systems are capable of measuring product quantities because of their accuracy, speed, and repeatability. For illustration, machine vision systems can be implemented on production lines and are capable of inspecting hundreds of parts per minute.

Reduced Downtime

Machine vision systems safeguard against parts damage by removing the physical contact between a test system and the manufactured parts. They also reduce the time and fees required for fixing mechanical components as wear and tear take their toll. Machine vision systems help increase productivity further by increasing operation times, since machines will require less attention. This means that production deadlines can be met with ease and consistency.

Increased Productivity

Reduced downtime will inherently lead to increased productivity. But machine vision systems will take this concept even further. A machine vision system is capable of delivering corrective commands roughly with a speed that is one second faster than even trained operators can. This helps with the reduction of the need for manual correction of a system. It also helps with the stabilization of productivity levels.

Print Defects Identified

The identification of printing anomalies like incorrect color shades, missing letters, or blemished prints can be difficult. But, with a machine vision system, this task is easily handled.

Enhanced Safety

There is a lower risk of employees suffering injuries when operating bulky, powerful machines since machine vision systems reduce both employee exposure to dangerous equipment and employee fatigue experienced while performing repetitive, mundane tasks. Since there is a reduction of human involvement in manufacturing with machine vision systems, they create safer working environments.

Product Flaw Detection

Machine vision systems are capable of detecting product abnormalities such as surface dents and scratches. If detection boundaries are carefully applied, acceptable flaws can be distinguished from unacceptable flaws.

More Accurate Measurement

The application of machine vision systems also involves the accurate determination of objects’ dimensions. Vision systems can locate and measure certain points on an image quicker and more accurately than people. These points include the radius, diameter, depth, and distance.

Object Location

Machine vision systems are most commonly used for locating objects in applications like robotic guidance. For example, a machine vision system may be employed to find the location of coordinates for a particular object’s position. This information will then be used for picking up the object or performing another process that is location-dependent. Machine vision systems are multifunctional and can be applied in many different ways during manufacturing processes.

Choosing the Right Machine Vision Systems Company

To make sure you have the most beneficial outcome when purchasing Machine Vision Systems from a Machine Vision Systems Company, it is important to compare at least 4 Suppliers using our Machine Vision Systems directory. Each Machine Vision Systems Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Machine Vision Systems company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Machine Vision Systems companies with the same message.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services