While hand sorting systems do work, they are not capable of the high-speed action of automated optical sorting systems. In some applications, such as the recycling of papers and glass, optical sorting systems are also more accurate than human sorting. Read More…

When it comes to machine vision systems, we have the tools to get the job done right. We work hard to provide the best solutions and products to meet our customers’ demand. It is our goal to work with you from start to finish on all aspects of design and production. We will do our best to provide the solution to even your most challenging requirements. Find out more by contacting us today!

A family-owned business since 1923, Barr-Thorp Electric Company, now known as Thorp Controls provides electrical control solutions for OEMs, system integrators, and industrial users. From sourcing to engineering to installation and beyond, you can rely on us for efficient, reliable solutions. Our goal is to provide you with the technology you need to be more profitable. Our machine vision...

PrimeTest Automation is a full service systems integration company with a talented in-house engineering team featuring mechanical, electrical, and software engineers. Services include: conveyor systems, machine vision components, robotic systems and rotary index dials. All systems are modeled using the latest 3-D design software, thoroughly reviewed with the customer.

Imperx Inc. is a designer and manufacturer of high performance machine vision products, specifically digital cameras and frame grabbers. Industries served include the aerospace, industrial, commercial, and military industries. Product applications include biometrics, aerial mapping, traffic management, surveillance, homeland security, medical imaging, printing, and more.

More Optical Sorting System Manufacturers

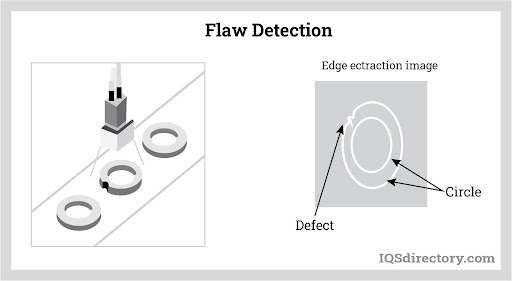

Optical sorting systems are used for multiple purposes in many different industries. They can be used in recycling plants to separate metals, plastics, papers, and glass from each other. In addition to sorting by material, optical systems are also capable of sorting by color and resin type. Especially in applications where large quantities of broken and mixed glass need to be sorted, optical sorting machines can be very advantageous. Despite the many advantages apparent over human vision, machine vision is inherently limited.

Even with nearly continual advancements of both hardware and software pertaining to this highly skilled field, computer vision programs lack the ability to adapt beyond pre-determined algorithms as human vision so aptly does. Machine vision works best when performing narrowly defined tasks, though continued advancements continually improve the performance possibilities of this technology.

Optical sorting systems can also be used in the food industry to remove pits from cherries and unwanted or damaged nuts from good ones. Infrared light can be used to "see" the interiors of foods in order to remove those affected by fungus or rotting. Optical sorting machines are also used to remove contaminants from popcorn, coffee, rice, and other food products. Optical sorting systems can also be come in a number of other configurations such as vision sensors, vision inspection systems, robotic vision, optical inspection systems, magnetic imaging, machine vision, laser inspection, CCD cameras and much more.

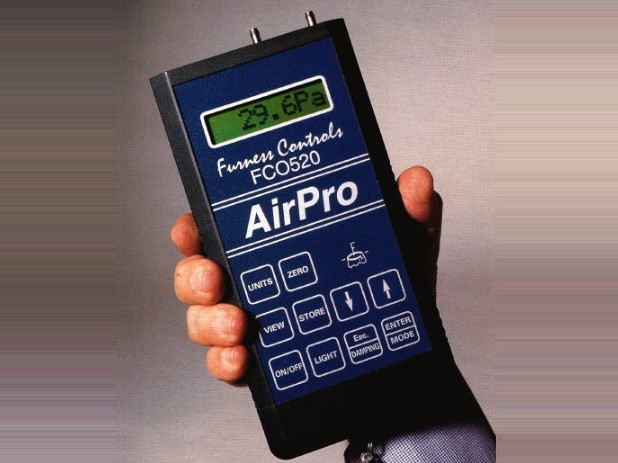

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services