A vision inspection system contains the technology that is based on image processing and specifically used for automating the inspection processes in production lines in many different industries. Vision inspection systems allow for the inspection and evaluation of product quality by computers through the use of industrial lights, cameras, and computer vision software. Read More…

When it comes to machine vision systems, we have the tools to get the job done right. We work hard to provide the best solutions and products to meet our customers’ demand. It is our goal to work with you from start to finish on all aspects of design and production. We will do our best to provide the solution to even your most challenging requirements. Find out more by contacting us today!

A family-owned business since 1923, Barr-Thorp Electric Company, now known as Thorp Controls provides electrical control solutions for OEMs, system integrators, and industrial users. From sourcing to engineering to installation and beyond, you can rely on us for efficient, reliable solutions. Our goal is to provide you with the technology you need to be more profitable. Our machine vision...

PrimeTest Automation is a full service systems integration company with a talented in-house engineering team featuring mechanical, electrical, and software engineers. Services include: conveyor systems, machine vision components, robotic systems and rotary index dials. All systems are modeled using the latest 3-D design software, thoroughly reviewed with the customer.

Imperx Inc. is a designer and manufacturer of high performance machine vision products, specifically digital cameras and frame grabbers. Industries served include the aerospace, industrial, commercial, and military industries. Product applications include biometrics, aerial mapping, traffic management, surveillance, homeland security, medical imaging, printing, and more.

More Vision Inspection System Manufacturers

What is a Vision Inspection System?

The technology of vision inspection systems is utilized for performing high-speed and reliable quality control.

This technology helps ensure the quality of the products and improve overall efficiency as manual labor is released from repetitive, as well as challenging, inspection tasks. Furthermore, through digitizing the inspection process and generating documenting data, vision inspection systems can be utilized to help generate production data and statistics.

Vision inspection systems help by facilitating production optimization. Because of their broad applications, as well as efficiency, vision inspection systems are already widely used in many industries including electronics, pharmaceuticals, food and beverage, automotive, labeling, printing, and packaging sectors. Many other industries, meanwhile, are just now beginning to realize their potential.

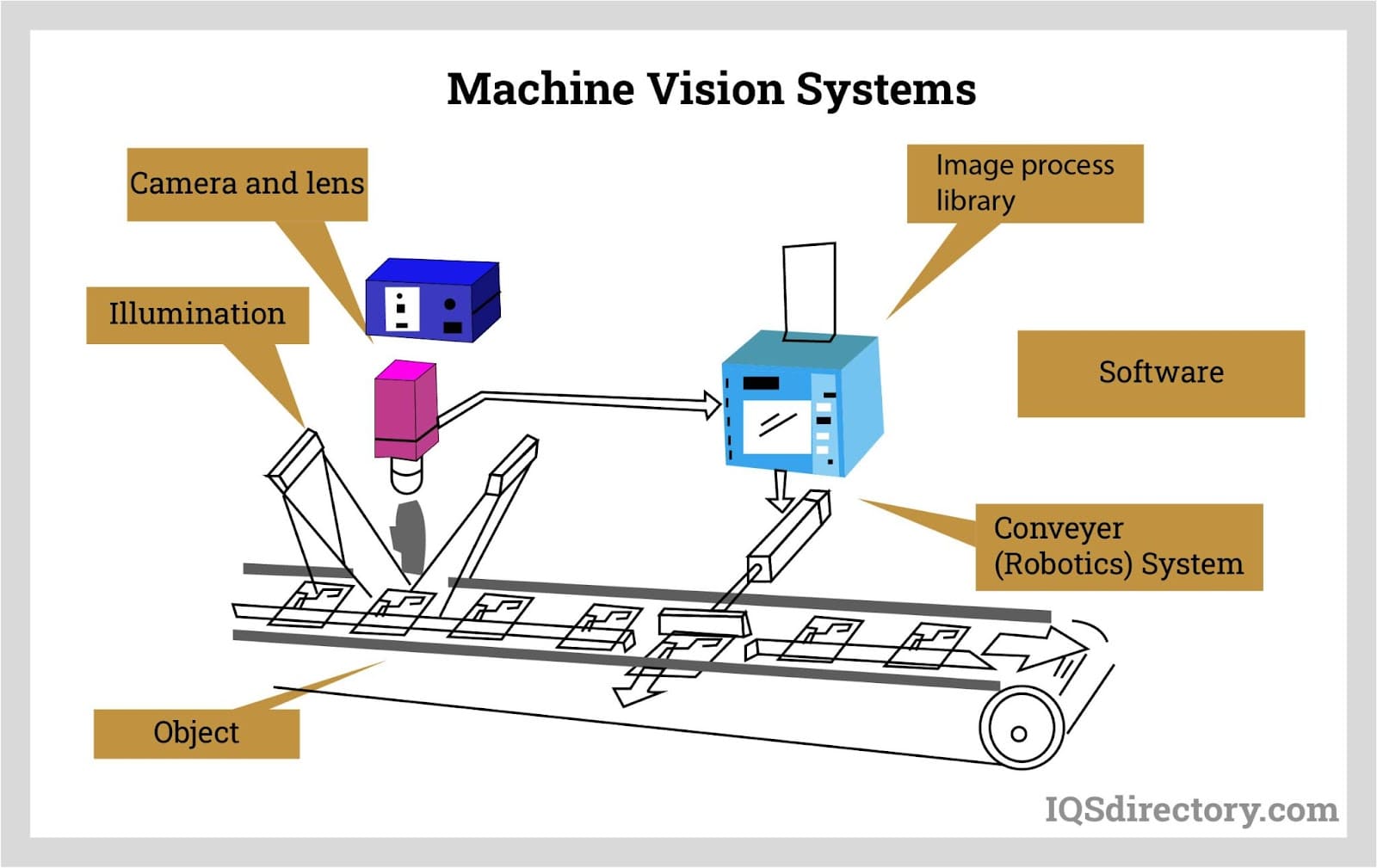

The Components of a Vision Inspection System

The components of a vision inspection system include the following:

- They utilize sensors that serve to identify the incoming objects’ presence.

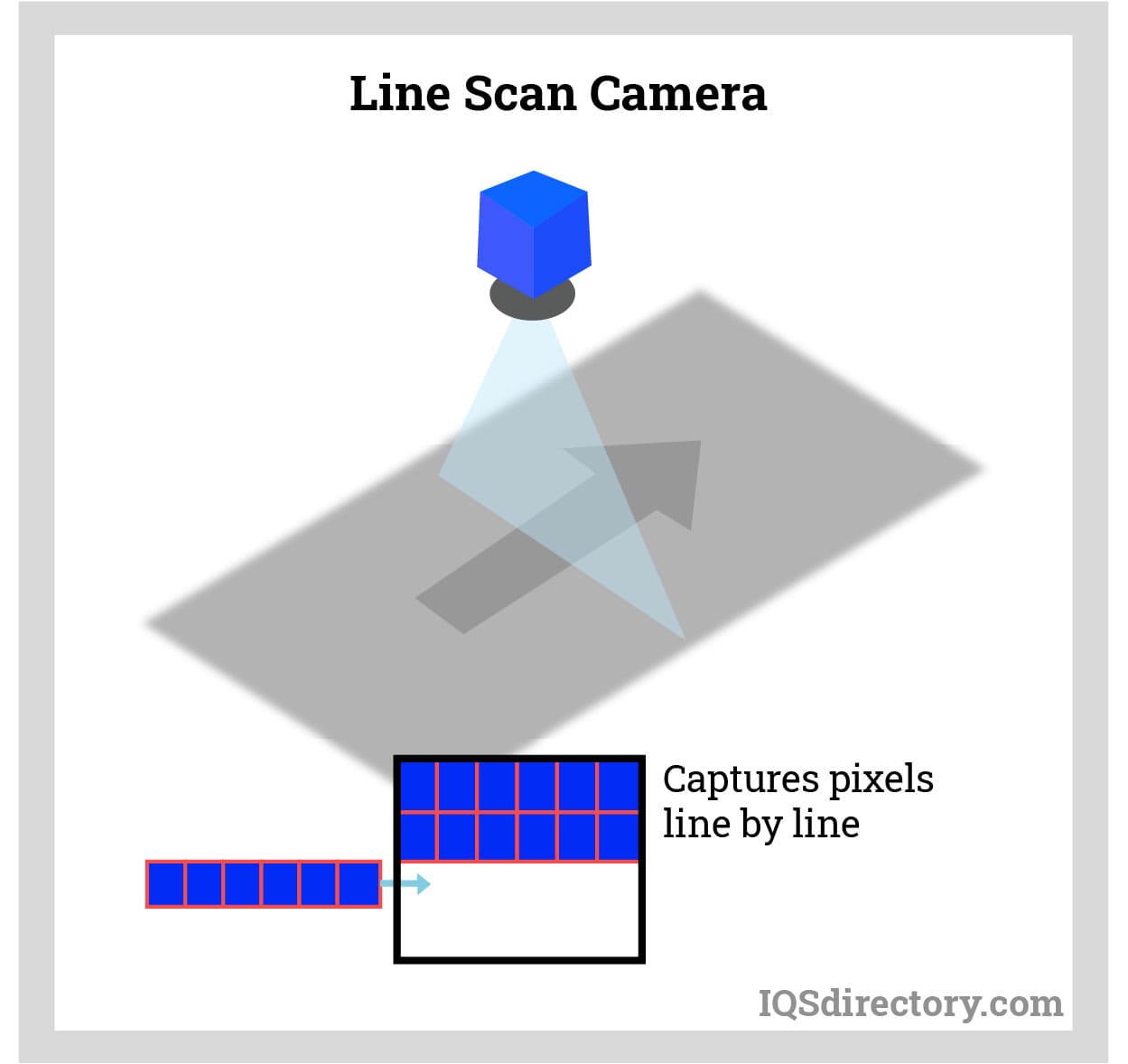

- Cameras are the eyes of the system. These are used to acquire images of the objects that need to be inspected.

- Their lights and housing ensure optimal light for the acquisition of the image.

- A PLC is used to control the system logic i.e. inputs, outputs as well as other actions from the components of the hardware.

- These systems then require an industrial computer that runs the vision inspection software required to analyze the images acquired and provide an HMI.

- Finally, an operator panel is required which is responsible for visualizing data and enabling operators to control the system.

How Vision Inspection Works

Image Acquisition

When an incoming object draws closer to the system, a sensor detects it. Light sources, as well as cameras, act on the input of the sensor by lighting up the area. They also capture an exact image of the object in real time.

Image Processing and Analysis

Algorithms as well as several specific filters are applied to pre-process the acquired image. This is done for detecting the product in the image and highlighting the key features of interest. Algorithms are then used based on the filtered image for generating a data object. The algorithm design impacts the efficiency of image processing and analysis.

Result Evaluation

The system’s software will then compare the extracted data object with a set of predefined tolerances, which defines the target quality level of a producer.

Decision

Finally, based on the set tolerances and the comparison between the processing results, decisions are then made by the system. At that time, the object that has been inspected will be given classification, for example, passed or failed.

Process Control

Other vision inspection systems use the gathered inspection data for spotting trends in production, and provide recommendations to the machine operators for production optimization. This can be achieved through data platforms that give production data overviews highlighting crucial production information.

Types of Vision Inspection Systems

The different types of vision inspection systems include:

PC Based

These systems have an industrial computer that is responsible for managing and communicating with all the peripheral devices like cameras and lighting components. PC-based vision inspection systems provide high computing power as well as flexibility. They are recommended for complex applications where there is a requirement for carrying out multiple inspection tasks at a faster rate using high-performance hardware. However, their size and cost can be significant factors to be considered.

Compact

This is a lighter version of a PC-based system. This type of vision inspection system may require some tradeoff between cost and performance but typically provides enough capability for less-demanding applications. This system consists of a graphics card that is responsible for acquiring and transferring the information elsewhere.

Smart Camera-Based

This is the simplest and cheapest solution of all vision inspection systems. This system is based on smart and intelligent cameras that are usually used in combination with standard optics as well as lighting. Although this system is typically recommended for simple applications, it has a very easy setup and it provides functionalities that are similar to those of classic vision systems in a very compact form factor.

Applications of Vision Inspection Systems

- Food and packaging appearance inspection

- Presence or absence check

- Color inspection

- Orientation check

- Label check, as well as verification

- Seal inspection, as well as validation

- Foreign object detection

Benefits of Vision Inspection Systems

- They provide automated quality control that allows the enjoyment of a reliable system that will deliver time and time again.

- A vision inspection system helps to ensure that every product a business produces will meet the specifications of the customer.

- These systems lead to higher quality as well as increased productivity.

- Vision inspection systems also lower the costs of production.

Choosing the Correct Vision Inspection Systems Company

To make sure you have the most productive outcome when purchasing Vision Inspection Systems from a Vision Inspection Systems Company, it is important to compare at least 5 Companies using our Vision Inspection Systems directory. Each Vision Inspection Systems Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Vision Inspection Systems business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Vision Inspection Systems businesses with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services