A vision system is a system that provides image-based inspection for different industrial and manufacturing applications. Smart cameras that have been calibrated for performing specific inspections automatically examine products during manufacturing or may adjust other processes in real time. Read More…

When it comes to machine vision systems, we have the tools to get the job done right. We work hard to provide the best solutions and products to meet our customers’ demand. It is our goal to work with you from start to finish on all aspects of design and production. We will do our best to provide the solution to even your most challenging requirements. Find out more by contacting us today!

A family-owned business since 1923, Barr-Thorp Electric Company, now known as Thorp Controls provides electrical control solutions for OEMs, system integrators, and industrial users. From sourcing to engineering to installation and beyond, you can rely on us for efficient, reliable solutions. Our goal is to provide you with the technology you need to be more profitable. Our machine vision...

PrimeTest Automation is a full service systems integration company with a talented in-house engineering team featuring mechanical, electrical, and software engineers. Services include: conveyor systems, machine vision components, robotic systems and rotary index dials. All systems are modeled using the latest 3-D design software, thoroughly reviewed with the customer.

Imperx Inc. is a designer and manufacturer of high performance machine vision products, specifically digital cameras and frame grabbers. Industries served include the aerospace, industrial, commercial, and military industries. Product applications include biometrics, aerial mapping, traffic management, surveillance, homeland security, medical imaging, printing, and more.

More Vision System Manufacturers

What is a Vision System?

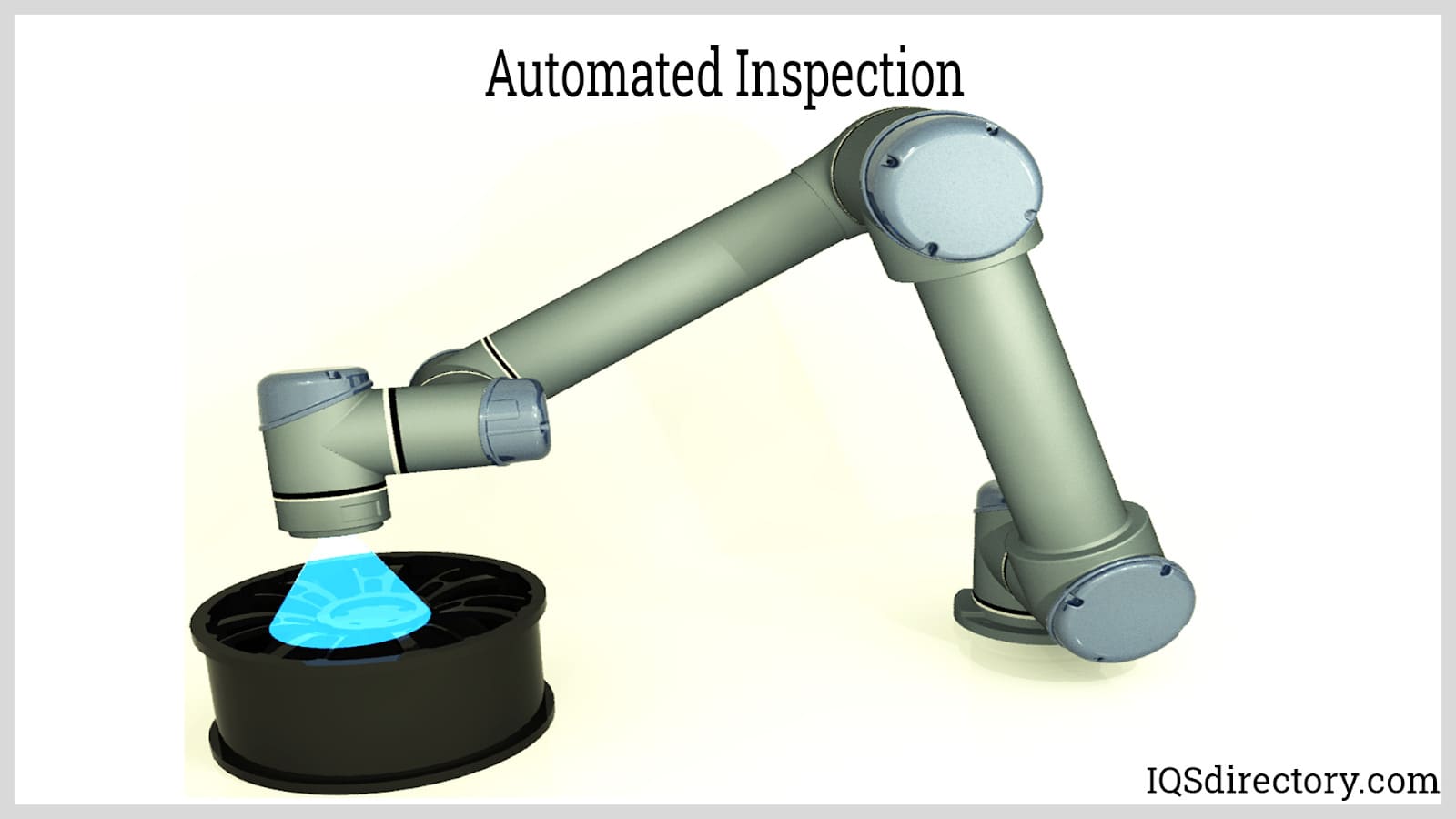

2D and 3D cameras are now used as parts of a vision system for automated inspection, quality control, robot guidance, product guidance, and many other industrial purposes.

There are many applications of vision systems. The type of vision system that is most suitable for a certain application depends on many factors including the specific properties of the process or products, what needs to be inspected, the inspection speed, and the budget available. Most inspections are carried out using either 1D, 2D, 3D, or area/line scan cameras.

Types of Vision Systems

The different types of vision systems include:

Process Control Vision Systems

Process control vision systems utilize process feedback for achieving a flawless process line using industrial process vision controls. Among the many functions they serve include the capturing and communication of measured values to a variety of data logging systems, using imaging systems for precise control of robot positioning, the capturing of historical data from a process, and the monitoring of events through event-capture technology.

Defect Inspection Vision Systems

These vision systems serve to catch and resolve product surface defects or packaging issues in real time. Examples of issues tracked through these systems include label placement verification, dent inspection, broken seals, missing parts, deformities, broken parts, etc.

Custom Packaging Inspection Vision Systems

These vision systems are responsible for limiting the false reject rate and meeting the exact standards and qualities required for the product. They are used to inspect for defects, dents, holes, and creases on various materials including plastics, damage, metals, or glass. Vision systems also check labels for wrinkles, skew, position, and date codes. Furthermore, they may be used to examine missing caps, molded features, crooked caps, correct seals, etc.

Print-and-Code Inspection Vision Systems

Print-and-code inspection vision systems are responsible for identifying incorrect or damaged labels on products before their release. They may be used for many purposes including the detection of poor quality text or inspecting pre-printed artwork, laser markings, ink-jet quality, chemical etchings, etc. Vision systems are used to check 1D barcodes and 2D data matrix codes' readability and matching of products. They also help in the verification of correct labeling for purposes ranging from guaranteeing the proper listing of ingredients to providing correct nutritional information.

Custom Web Inspection Vision Systems

These vision systems utilize real-time processing to eliminate tears, detect improper webbing, prevent holes, and for various other purposes. These systems are also employed in the inspection of barcodes and 2D codes, checking artwork, and monitoring print quality.

Custom Tolerance Measurement Vision Systems

Custom tolerance measurement vision systems ensure the quality of products as well as repeatable production standards. They are capable of revealing valuable process information. Examples of the functions they may serve include verifying of thread counts or the tolerances of different parts, providing machine vision measurements as well as statistics, checking the tolerance of a final machined part, camera and laser scanning, comparing finished products with CAD images, heat seal inspection, the analyzing infrared cameras, and radiometric analysis.

Applications of a Vision System

- Vision systems are utilized in the manufacturing industries for the inspection of random samples. They can also be used for in-line inspection of all samples.

- They are used for quality control/appearance inspections.

- They are utilized for dimension inspection and counting.

- They are used for picking and positioning.

- Vision systems can be used for defect detection and pattern matching.

- They can be used for automated vision testing as well as for measurement verification.

Benefits of a Vision System

- Vision systems are capable of performing tedious tasks in hazardous environments.

- They reduce human intervention, thus eliminating the possibilities of human contamination and potentially reducing employee errors.

- Vision systems automate repetitive and arduous tasks. This will, in turn, ensure a seamless workflow and also provide employees the time to indulge in creative thinking strategies and problem-solving exercises.

- These systems reduce operational and maintenance costs drastically, and they also save hours of manual labor.

- They are capable of delivering unparalleled accuracy and precision; they are able to detect even miniature defects not noticed by people.

Choosing the Correct Vision System Company

To make sure you have the most positive outcome when purchasing Vision Systems from a Vision System Company, it is important to compare at least Companies using our list of Vision System suppliers. Each Vision System Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Vision System business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Vision System companies with the same quote.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services