Micro Quality Corporation

Micro Quality CorporationRequest A Quote

Deerfield Beach, FLMicro Quality Corporation, located in Deerfield Beach, FL, is a reputable provider of Machine Vision Systems solutions. With a strong commitment to precision, reliability, and customer satisfaction, we specialize in delivering cutting-edge technologies that optimize manufacturing processes, enhance quality control, and drive automation. Machine Vision Systems play a critical role in today's industrial landscape, enabling businesses to achieve higher levels of accuracy, efficiency, and productivity. At Micro Quality Corporation, we leverage our expertise in imaging technology, software development, and automation to develop and implement advanced solutions that meet the unique needs of our clients. Key Features of our Machine Vision Systems: 1. High-Quality Imaging: Micro Quality Corporation's Machine Vision Systems integrate advanced cameras, sensors, and lighting techniques to capture high-resolution images with exceptional clarity and precision. This ensures accurate inspection, measurement, and identification of objects, even in challenging and demanding production environments. 2. Advanced Image Processing: We utilize state-of-the-art image processing algorithms, pattern recognition techniques, and artificial intelligence to analyze visual data captured by our systems. This enables real-time defect detection, quality control, sorting, grading, and other complex image analysis tasks with utmost accuracy and efficiency. 3. Integration Flexibility: Micro Quality Corporation's Machine Vision Systems are designed for seamless integration with existing manufacturing processes and equipment. Our solutions can be easily integrated with robotic systems, conveyors, assembly lines, and other machinery, facilitating streamlined workflow and efficient data exchange. 4. Customization and Scalability: We offer tailored Machine Vision Systems that are customized to meet the specific requirements of each client. Our team of experienced engineers collaborates closely with clients to design solutions that are scalable, adaptable, and aligned with their evolving production needs. 5. User-Friendly Interface: Micro Quality Corporation's Machine Vision Systems feature intuitive user interfaces and software platforms that allow for easy system configuration, monitoring, and control. Operators can efficiently manage system parameters, access real-time data, and make adjustments to optimize performance and productivity. Services Offered: 1. Consultation and Needs Assessment: Micro Quality Corporation provides comprehensive consultation services, working closely with clients to understand their production objectives and challenges. Our experts conduct detailed needs assessments to identify the most suitable Machine Vision Systems for their specific applications. 2. System Design and Development: Our team of skilled engineers and technicians designs and develops customized Machine Vision Systems tailored to meet the unique requirements of each client. We handle all aspects of system design, including hardware selection, software development, and seamless integration with existing infrastructure. 3. Installation and Commissioning: Micro Quality Corporation's experienced technicians ensure smooth installation and commissioning of Machine Vision Systems on-site. We conduct thorough testing, calibration, and system validation to ensure optimal performance and minimal disruption to production operations. 4. Training and Support: We provide comprehensive training programs to empower clients' operators and maintenance personnel with the necessary skills to operate and maintain the Machine Vision Systems effectively. Our dedicated support team is available to provide ongoing assistance, troubleshooting, and maintenance services. Industries Served: Micro Quality Corporation's Machine Vision Systems cater to a wide range of industries, including automotive, electronics, medical devices, pharmaceuticals, packaging, and more. Our solutions have been successfully deployed for quality inspection, process control, product traceability, and other critical applications in diverse manufacturing environments. Micro Quality Corporation is dedicated to delivering advanced Machine Vision Systems that drive operational excellence, enhance product quality, and optimize manufacturing processes. With our expertise, technological advancements, and commitment to customer satisfaction, we are proud to be the trusted partner for companies seeking reliable, efficient, and innovative vision technology solutions.

Calibration Services

Calibration Services Clean Rooms

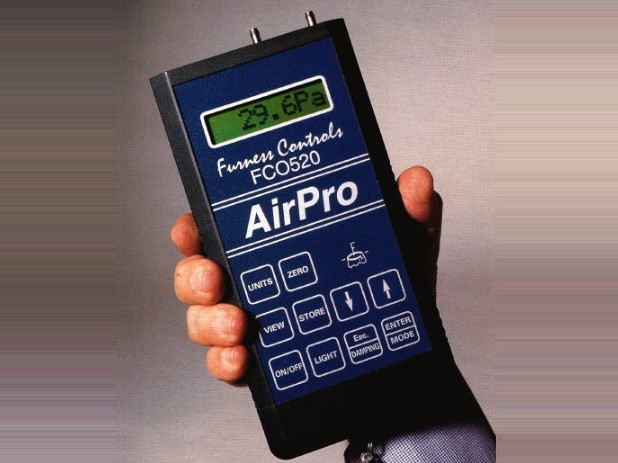

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services